|

|

|

|

Optical Sciences Corporation's engineering expertise covers multiple disciplines in support of

the US Army, NASA, and private industry. OSC personnel are specialists in the areas of infrared

engineering, optical lens design, mechanical systems design, electronics design, and software

development.

Infrared Systems Engineering

Optical Sciences Corporation personnel have supported the test and evaluation of infrared

missiles, sensors, and seekers at the CCDC AvMC Hardware-in-the-Loop (HWIL) facilities

since 1989. This support includes key roles in test planning, seeker/unit-under-test (UUT)

integration, data collection, and performance evaluation. Additionally, OSC provides complete

support for the day-to-day operation of the infrared system test equipment used to actively

stimulate the missile/sensor hardware within the HWIL test environment. This test equipment

includes several state-of-the-art

dynamic infrared scene projection (IRSP) systems such as

the:

Optical Sciences Corporation personnel have supported the test and evaluation of infrared

missiles, sensors, and seekers at the CCDC AvMC Hardware-in-the-Loop (HWIL) facilities

since 1989. This support includes key roles in test planning, seeker/unit-under-test (UUT)

integration, data collection, and performance evaluation. Additionally, OSC provides complete

support for the day-to-day operation of the infrared system test equipment used to actively

stimulate the missile/sensor hardware within the HWIL test environment. This test equipment

includes several state-of-the-art

dynamic infrared scene projection (IRSP) systems such as

the:

- Honeywell Emitter Array Based IRSP Systems

- SBIR Emitter Array Based IRSP Systems

- DMD Based IRSP Systems

- Laser Diode Array Projector (LDAP) System

- Infrared Zoom Projector System

- Point Source Projector System

Optical Sciences Corporation infrared engineering activities also include the manufacturing of

custom production line test stations. OSC has delivered these test station units for the in-line

evaluation of production sub-munitions incorporating an infrared sensor.

Click for more information on Dynamic Infrared Scene Projectors (Emitter, DMD & Laser Based)

Optical Engineering

|

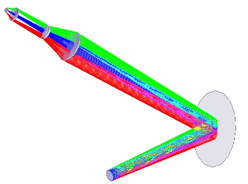

OSC optical engineers are specifically trained in the areas of optical systems design and

analysis. OSC routinely designs optical assemblies for integration into scene projector and

test station systems. These systems cover the ultraviolet, visible, mid-, and long-wave infrared

wavebands. OSC works closely with manufacturers to insure these systems meet the stringent

technical requirements set by today's state-of-the-art defense systems. Many of these projector

systems incorporate unique features including: anamorphic optics, dichroics, diffractive lens

surfaces, extended exit pupils, and multi-faceted polygon scanners. OSC engineers insure the

optical quality of the simulated dynamic imagery meets or exceeds the standards set by the Unit

Under Test (UUT).

|

Mechanical Engineering

|

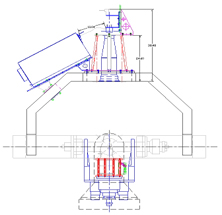

OSC mechanical engineers provide daily support in the design of custom test equipment to support

leading-edge HWIL testing. Test fixtures, mountings, motorized irises, and enclosures have been

designed, fabricated and tested. OSC optical and mechanical engineers work together to insure

all positional tolerancing requirements are met or exceeded for these state-of-the-art projector

systems.

|

|

Electrical Engineering

|

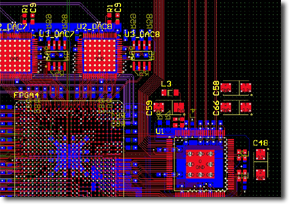

OSC engineers provide daily support in the development, test, maintainence and operation of

key electronic systems and subsystems in the operation of the infrared test equipment. OSC

electrical engineers provide digital and analog design expertise for the development of

state-of-the-art test systems.

|

Software Development

|

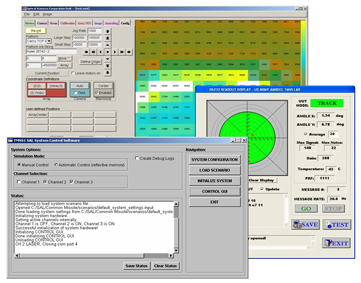

OSC personnel have developed extensive sytem control software packages for the operation of

test equipment used in the HWIL environment. These are typically PC-based Windows applications

providing an intuitive, powerful GUI for control of all test functionality required to

initialize, operate, debug, and collect data during the daily operation of the infrared

scene projectors and infrared test station equipment. OSC also provides custom image processing

and data reduction software support to each of the CCDC AvMC infrared HWIL laboratories.

This support plays a key role in the verification and validation of the infrared projector

systems within the AvMC facilities.

|

|

|

|

|

|

|

|

|